B7232C.T.P4S

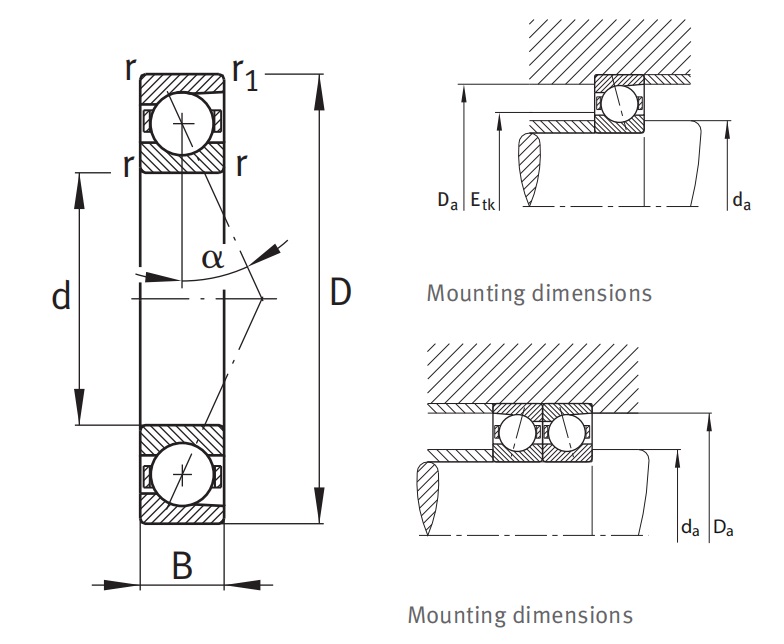

Detailed parameters and installation dimensions:

| Part Number | B7232C.T.P4S |

| Design Type | B = Standard bearing, Lager balls, Steel balls |

| Series | B72..-C.T.P4S |

| Contact angle - α | (C) 15 ° |

| Dimension series | 72 (Heavy series) |

| Reference From | FAG B7232C.T.P4S |

| Dimension Inside - d φ (mm) | 160 |

| Dimension Outside - D Φ (mm) | 290 |

| Dimension Width - B (mm) | 48 |

| Accuracy class | P4S |

| Dimension - r(min.) | 3 mm | 0.118 inch |

| Dimension - r1(min.) | 3 mm | 0.118 inch |

| Seal | Open |

| Reference speed (grease) - nB | 99954 min–1 |

| Limiting speed (oil) - nG | 169960 min–1 |

| Mounting dimensions - da(h12) | 191 mm | 7.520 inch |

| Mounting dimensions - Da(H12) | 259 mm | 10.197 inch |

| Bearing Type | Super Precision Angular Contact Ball Bearing |

| Row No. | One |

| Bore Type | Z = Cylindrical bore |

| Mounting dimensions - Etk(nom.) | 216.9 mm | 8.539 inch |

| Dimension Inside - d φ (inch) | 6.299 |

| Dimension Outside - D Φ (inch) | 11.417 |

| Dimension Width - B (inch) | 1.890 |

| Manufacturer Part Code | B7232CTP4S , B7232C-T-P4S |

| Temperature - T(min) | -30°C |

| Temperature - T(max) | +100°C |

| Units | Metric |

| Radial Dynamic Capacity - Cr | 6364 N | 1430 lbf |

| Bearing Mass - m | 12.9 kg | 28.439 lb |

| Cage | T = Laminated fabric, guidance on outer ring |

| Radial static Capacity - C0r | 1340 N | 301 lbf |

| Preload force - Fv L | 1504 N | 338 lbf |

| Preload force - Fv M | 4684 N | 1052 lbf |

| Preload force - Fv H | 9290 N | 2088 lbf |

| Ball Material | GCr15SiMn |

| Axial rigidity - ca L | 172 N/μm |

| Axial rigidity - ca M | 281 N/μm |

| Axial rigidity - ca H | 400 N/μm |

| Ring Material | GCr15SiMn |

| Lift-off force - KaE L | 4621 N | 1038 lbf |

| Lift-off force - KaE M | 15329 N | 3445 lbf |

| Lift-off force - KaE H | 32402 N | 7283 lbf |

NOTE: All other trademarks are the property of their respective owners, used for the purpose of compatibility description and product identification only. Tradebearings is not affiliated with, endorsed by, or sponsored by the holders of these trademarks.

B7232C.T.P4S refers to a specialized type of B72..-C.T.P4S Super Precision Angular Contact Ball Bearing, with dimensions 160 mm (Bore) x 290 mm (OD) x 48 mm (Width), designed for Limits of rigidity, super precision and stability, primarily used in CNC machine tool spindles and other high-precision machinery, the grease speed ratings: 99954 rpm, oil speed ratings: 169960 rpm, featuring One (row) construction T = Laminated fabric, guidance on outer ring retainer, advanced Open, P4S (precision) for applications the field of precision machinery, especially high-speed and high-precision spindle systems, requiring high running accuracy and the accommodation of radial and axial loads simultaneously. . the Basic load can reach (dynamic radial:6364, static radial:1340, ), It weight approximately 12.9 kilogram.

- Min. Order: 1 Piece/(B7232C.T.P4S, 160 = ID, 290 = OD, 48 = B, 12.9 kg) or according to different suppliers

- Price: Different brands, different quality, different B7232C.T.P4S prices, different suppliers and different quality determine different prices, you can ask the supplier in detail for the price according to your own needs.

- Precision Rating: DIN: P2~P0; ANSI: ABEC9~ABEC1; JIS: JIS~JIS0; ISO: CLASS2~NORMAL CLASS; GB/T30794 B~G

- Inquiry ways: The right of the inquiry form, Email, skype, Whatsapp

Luoyang Yeda High Speed Precision Heavy Duty Bearings Co.,Ltd.

Email: [email protected] Tel: 0086-0379-18737946587 Mob No.:008618737946587 2018-12-29B7232C.T.P4S is widely used in CNC machine tools, high precision rotary table and high

precision equipment

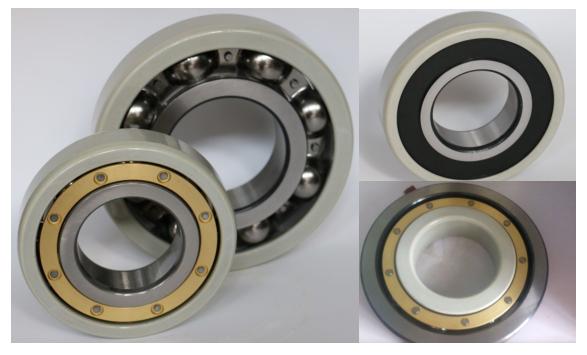

Description:

Material: Ceramics,Hybrid(steel ball rings and Ceramic ball),Stainless,plastic.

Preloaded mark:

EL: Micro preloaded

L : Light preload

M : Medium preloade

H : Heavy preloaded

Our company has a large number of high-precision Angular Contact Ball Bearings inventory,

complete models.

Preferential price bearing models as follows:308 PCS B7232C.T.P4S,167 PCS HCB7019E.T.P4S.UL,

678 PCS SC7007 FB/P7,

533 PCS HCS71915C.T.P4S.UL,

897 PCS 2MM9340WICRSUL TIM Superprecision,

111 PCS HCB7006C.2RSD.T.P4S.UL,

359 PCS 7948A5TRSULP4,

283 PCS HCB71906E.T.P4S.UL,

903 PCS B7024E.T.P4S.UL.