HCB7222-C-T-P4S

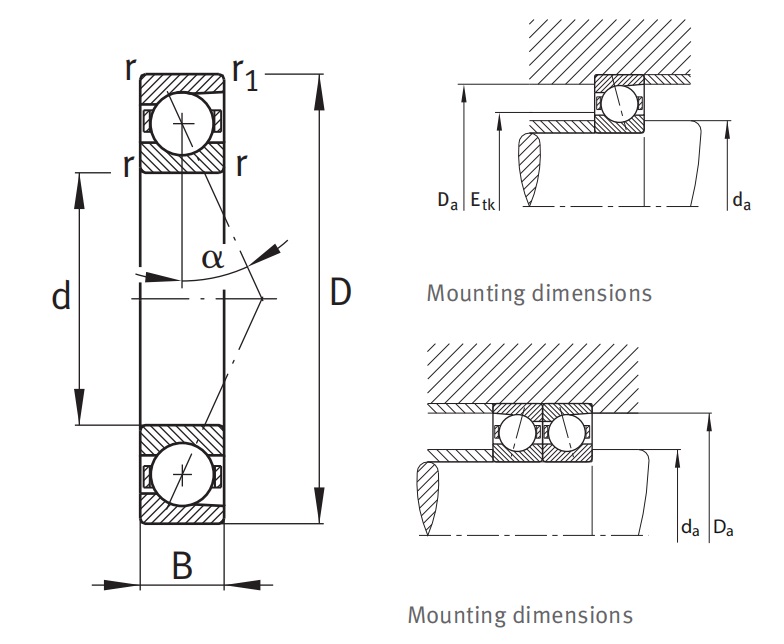

Detailed parameters and installation dimensions:

| Part Number | HCB7222-C-T-P4S |

| Design Type | HCB = Hybrid Standard bearing, Lager balls, Ceramic balls |

| Series | HCB72..-C-T-P4S |

| Contact angle - α | (C) 15 ° |

| Dimension series | 72 (Heavy series) |

| Reference From | FAG HCB7222-C-T-P4S |

| Dimension Inside - d φ (mm) | 110 |

| Dimension Outside - D Φ (mm) | 200 |

| Dimension Width - B (mm) | 38 |

| Accuracy class | P4S |

| Dimension - r(min.) | 2.1 mm | 0.083 inch |

| Dimension - r1(min.) | 2.1 mm | 0.083 inch |

| Seal | Open |

| Reference speed (grease) - nB | 8429 min–1 |

| Limiting speed (oil) - nG | 13954 min–1 |

| Mounting dimensions - da(h12) | 126.5 mm | 4.980 inch |

| Mounting dimensions - Da(H12) | 183.5 mm | 7.224 inch |

| Bearing Type | Super Precision Hybrid Angular Contact Ball Bearing |

| Row No. | One |

| Bore Type | Z = Cylindrical bore |

| Mounting dimensions - Etk(nom.) | 148.7 mm | 5.854 inch |

| Dimension Inside - d φ (inch) | 4.331 |

| Dimension Outside - D Φ (inch) | 7.874 |

| Dimension Width - B (inch) | 1.496 |

| Manufacturer Part Code | HCB7222CTP4S , HCB7222C-T-P4S |

| Temperature - T(min) | -30°C |

| Temperature - T(max) | +100°C |

| Units | Metric |

| Radial Dynamic Capacity - Cr | 163932 N | 36851 lbf |

| Bearing Mass - m | 3.97 kg | 8.752 lb |

| Cage | T = Laminated fabric, guidance on outer ring |

| Radial static Capacity - C0r | 100865 N | 22674 lbf |

| Preload force - Fv L | 556 N | 124 lbf |

| Preload force - Fv M | 1779 N | 399 lbf |

| Preload force - Fv H | 3553 N | 798 lbf |

| Ball Material | Ceramic |

| Axial rigidity - ca L | 107 N/μm |

| Axial rigidity - ca M | 180 N/μm |

| Axial rigidity - ca H | 251 N/μm |

| Ring Material | GCr15SiMn |

| Lift-off force - KaE L | 1625 N | 365 lbf |

| Lift-off force - KaE M | 5509 N | 1238 lbf |

| Lift-off force - KaE H | 11751 N | 2641 lbf |

NOTE: All other trademarks are the property of their respective owners, used for the purpose of compatibility description and product identification only. Tradebearings is not affiliated with, endorsed by, or sponsored by the holders of these trademarks.

HCB7222-C-T-P4S refers to a specialized type of HCB72..-C-T-P4S Super Precision Hybrid Angular Contact Ball Bearing, with dimensions 110 mm (Bore) x 200 mm (OD) x 38 mm (Width), designed for ceramic balls materials, high speed, ultra-high precision and high thermal stability, corrosion resistant, non-magnetic, primarily used in Machine tool spindle, robot reducer and high-precision machinery, the grease speed ratings: 8429 rpm, oil speed ratings: 13954 rpm, featuring One (row) construction T = Laminated fabric, guidance on outer ring retainer, advanced Open, P4S (precision) for applications In high-speed, high-precision, high-rigidity, and extreme environments, it provides extremely stable and reliable rotary supports for modern high-end manufacturing, high-tech industries, and high-precision rotating equipment. the Basic load can reach (dynamic radial:163932, static radial:100865, ), It weight approximately 3.97 kilogram.

- Min. Order: 1 Piece/(HCB7222-C-T-P4S, 110 = ID, 200 = OD, 38 = B, 3.97 kg) or according to different suppliers

- Price: Different brands, different quality, different HCB7222-C-T-P4S prices, different suppliers and different quality determine different prices, you can ask the supplier in detail for the price according to your own needs.

- Precision Rating: DIN: P2~P0; ANSI: ABEC9~ABEC1; JIS: JIS~JIS0; ISO: CLASS2~NORMAL CLASS; GB/T30794 B~G

- Inquiry ways: The right of the inquiry form, Email, skype, Whatsapp

What are the Benefits of choosing HCB7222-C-T-P4S bearings?

1. Ultra-high speed: The low density of ceramic balls (approximately 40% of steel balls) results in low centrifugal force, significantly increasing the maximum speed.

2. Long lifespan: High hardness and low coefficient of friction lead to minimal wear; the material itself is corrosion-resistant, high-temperature resistant, and has a long fatigue life.

3. Low heat generation: Good self-lubricating properties result in low temperature rise during operation and excellent thermal stability.

4. High rigidity: High elastic modulus (approximately 1.5 times that of steel) provides strong resistance to deformation and more stable machining accuracy.

5. Insulation: Excellent electrical insulation properties (high resistivity) prevent electrolytic corrosion damage, making it suitable for applications such as motors.

6. Low maintenance: Low lubrication requirements ensure high long-term operational reliability and reduce downtime for maintenance.

The HCB7222-C-T-P4S bearings adopts a ceramic balls materials, high speed, ultra-high precision and high thermal stability, corrosion resistant, non-magnetic design, featuring One (row) construction from HCB72..-C-T-P4S (series), optimal operating temperature is generally -30 to +100 degrees Celsius. With grade precision of P4S and the equipment operates more stably , and the maximum speed can reach (Limit Speed Ratings (grease) rpm:8429 Limit Speed Ratings (oil) rpm:13954).

What are the applications of the HCB7222-C-T-P4S bearing?

Machine tool spindles: Improve ultimate speed and machining accuracy, extend tool life.

Semiconductor equipment: Meet clean vacuum environment requirements, ensure micron-level positioning.

Aerospace: Reduce weight, withstand temperature differences, and meet high reliability requirements.

High-speed motors: Reduce centrifugal force and temperature rise, achieve ultra-high speed operation.

Medical devices: Quiet and stable operation, meet sterility and long lifespan requirements.

Precision instruments: Reduce vibration and thermal deformation, ensure measurement repeatability.

Robotics: Improve joint response speed and enhance motion trajectory accuracy.