KLK SO 1100-24

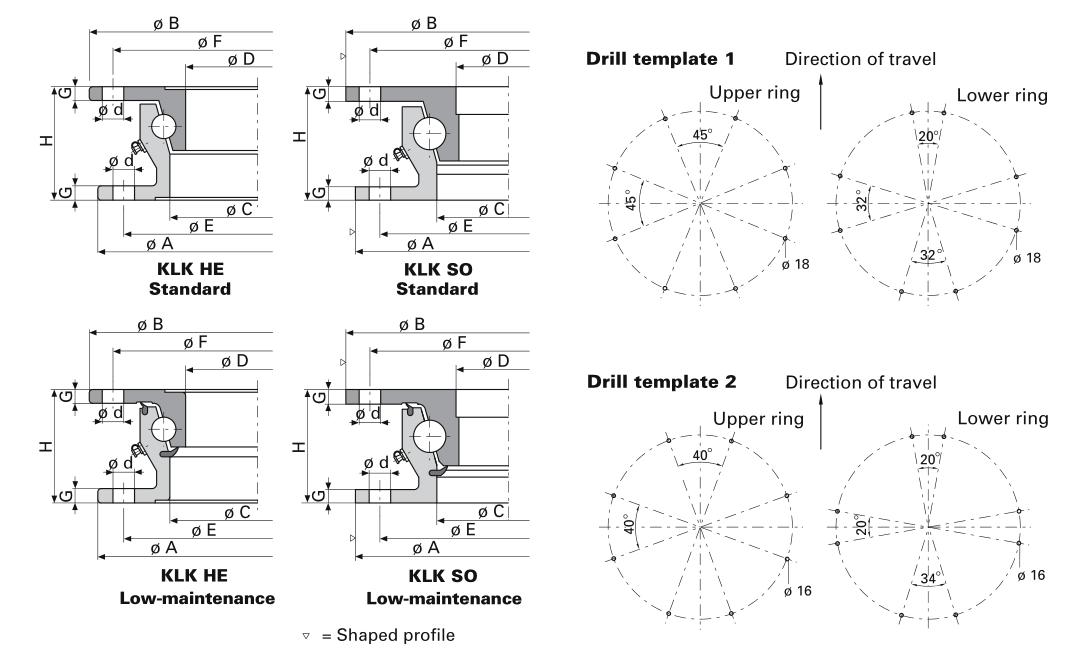

Detailed parameters and installation dimensions:

A: 1095 mm, B: 1108 mm, C: 981 mm, D: 950 mm, E: 1060 mm, F: 1074 mm, d: 18 mm, G: 10 mm, H: 90 mm, Permitted axial load (kN): 160 , WA: Standard , Drill template No.: 1

NOTE: All other trademarks are the property of their respective owners, used for the purpose of compatibility description and product identification only. Tradebearings is not affiliated with, endorsed by, or sponsored by the holders of these trademarks.

KLK SO 1100-24 refers to a specialized type of large Slewing ring bearings, with dimensions 950 mm (Bore) x 1095 mm (OD) x 90 mm (Width), designed for Integrated transmission, ultra-high load capacity, simplified structure, primarily used in excavators, cranes, wind turbines, for applications large, heavy-duty, heavy loads, low-speed rotation It weight approximately 75 kilogram.

Slewing ring bearings (KLK SO 1100-24) features:

Highly integrated structure and compact design: Integrating multiple load-bearing functions within a single unit significantly saves installation space and structural weight.

High load-bearing capacity: Specifically designed to withstand enormous axial load, radial load and tilting moment, which is beyond the capabilities of ordinary bearings.

High rotational accuracy and rigidity: Precision machining and pre-tensioning provide smooth and precise rotational motion, ensuring equipment operational stability.

Simplified design and assembly: Users only need to fix the inner or outer ring of the bearing to the main unit and base, respectively, greatly simplifying the design, manufacturing, and assembly process of the main unit.

Easy maintenance: Typically designed with lubrication channels and sealing devices, facilitating regular grease replenishment, minimizing maintenance workload, and extending service life.

Integratable drive function: The bearing raceways typically have internal or external teeth that can directly mesh with the drive pinion, eliminating the need for additional slewing bearing devices.

Flexible configuration: Depending on the load type, different rolling elements (balls, cylindrical rollers, crossed rollers) and arrangements (single row, double row, triple row) can be selected.

The KLK SO 1100-24 bearings adopts a Integrated transmission, ultra-high load capacity, simplified structure design, the equipment operates more stably .

Slewing ring bearings (KLK SO 1100-24) application:

access platforms; bucket wheel excavators; conveyor booms; cranes of all types; small, medium and large excavators; indexing tables; ladle turrets; offshore applications; robots; railway bogies; rotary platforms; stackers; solar mirrors; tunnel boring machines; wind turbines

Slewing ring bearings Selection:

Slewing Bearing Selection

The core of selection is translating actual operating conditions into bearing load-bearing capacity requirements and ensuring compatibility with the installation and drive system.

Step 1: Define Application Conditions and Loads

Instead of simply looking at the "rated load," a detailed list of the maximum forces exerted on the bearing under all operating conditions, including actual operation, extreme weather, and testing, must be provided. This list should be simplified to the axial force, radial force, and overturning moment acting at the bearing center. Factors such as rotational speed, accuracy requirements, operating temperature range, and environmental conditions (e.g., dust, corrosion) must also be considered.

Step 2: Introduce a Service Factor

Multiply the calculated load by the appropriate service factor to compensate for the effects of impact loads and operating frequency. Service factors vary significantly depending on the application. For example:

1. Wheeled mobile cranes: 1.00

2. Tracked cranes: 1.10

3. Excavators (hydraulic-limited): 1.50

Step 3: Selecting Bearing Type and Size

Based on load size and type:

1. Single-row four-point contact ball bearings: Suitable for medium loads, high speeds, and compact applications, such as small cranes and aerial work platforms.

2. Double/triple-row roller bearings: Suitable for heavy loads and equipment requiring high rigidity, such as large excavators and offshore cranes.

Next, compare the load multiplied by the service factor with the load capacity curve provided by the manufacturer. All load combinations must be below the curve. As a rule of thumb, the maximum thrust rating of the bearing should be greater than three times the maximum working thrust to ensure sufficient rigidity of the support structure.

Step 4: Determining Gear Parameters and Mounting Interface

If gear integration is required, determine the required gear module, tooth surface hardness, helix direction, and rated load. Simultaneously, confirm the bearing mounting hole positions, diameter, and connection method (internal/external/toothless) of the upper and lower support structures.

Step 5: Verify the connecting bolts

Bolt selection is crucial. SAE J429 Grade 8 or ISO 898-1 Class 10.9 bolts or higher strength are generally recommended. The final bolt quantity, specifications, and preload must be verified by the equipment designer based on the actual load, and cannot rely solely on the bearing sample.

Slewing ring bearings (KLK SO 1100-24) Install:

Key Points for Slewing Bearing Installation

Proper installation ensures the bearing achieves its design performance and prevents premature failure.

Step 1: Preparation and Inspection Before Installation

Support Structure: The mounting surface must have sufficient rigidity and flatness. Thin shims are strictly prohibited; thick steel plates with reinforcing ribs are recommended. The deflection of the support structure must be controlled within the manufacturer's allowable range (usually related to the bearing pitch circle diameter and rolling element diameter).

Surface Treatment: The mounting surface must be precision machined, and the flatness tolerance must meet the manufacturer's requirements (e.g., comparable to the flatness of the bearing race). Thoroughly clean the mounting surface; any tiny debris or burrs may cause bearing deformation after installation.

Step 2: Lifting and Positioning

Use eye bolts or flexible slings for lifting, avoiding damage to the gear teeth or mounting surface. Gently place the bearing on the clean mounting surface, using the locating stops of the inner and outer rings to assist alignment and improve gear meshing accuracy.

Step 3: Bolt Tightening

Lubrication and Washers: Apply a small amount of lubricant to the bolt threads and head, and use hardened flat washers.

Tightening Sequence: Tighten in three steps using a diagonal, star-shaped pattern:

Pre-tighten to 30% of the final torque

Increase to 80% of the final torque

Final tightening to 100% of the design torque

Tools: A calibrated torque wrench or hydraulic bolt tensioner is recommended to ensure even and accurate pre-tightening force.

Step 4: Post-Installation Inspection

After all bolts are tightened, check the gear backlash and bearing rotation torque. A significant difference between the post-installation torque and the pre-installation torque indicates potential installation deformation or misalignment. Simultaneously, confirm that the loading hole (ball hole) is located in the light-load zone to avoid premature failure due to stress concentration.

Slewing ring bearings (KLK SO 1100-24) Special Note:

Special Notes:

Rigidity is more important than capacity: Never attempt to compensate for insufficient rigidity in the support structure with higher capacity bearings. An unstable structure will result in uneven load distribution, causing abnormal stress on bearings, gears, and bolts.

Bolts are the weakest link: Bolt failure is one of the most common failure modes of slewing bearings. Always use the correct grade of bolts (e.g., 10.9) and strictly adhere to tightening procedures. Bolt holes should be evenly distributed and rounded, avoiding placement of bolts only in the main load-bearing area.

Lubrication is the lifeline: A relubrication system is essential. For intermittently operating equipment (e.g., excavators), it is recommended to add grease every 100 working hours; for continuously operating equipment (e.g., tunnel boring machines), daily grease is recommended. Gears also require lubrication.

Beware of mounting surface deformation: Welded structures (e.g., backing plates) are prone to deformation due to welding heat input. Ensure backing plates are thick enough to resist welding deformation and fit tightly against the base material to prevent gaps, which could cause bolts to bear additional alternating loads and fracture due to fatigue.

Proper storage: Bearings should be stored in a clean, dry indoor environment. If the storage period exceeds one year, re-lubrication is required before installation. Long-term outdoor storage may lead to rust and seal damage.

Have you determined the specific application equipment (e.g., crane, excavator, or wind turbine)? If you have specific load parameters, I can help you further analyze the selection criteria.

- Min. Order: 1 Piece/(KLK SO 1100-24, 950 = ID, 1095 = OD, 90 = B, 75 kg) or according to different suppliers

- Price: Different brands, different quality, different KLK SO 1100-24 prices, different suppliers and different quality determine different prices, you can ask the supplier in detail for the price according to your own needs.

- Precision Rating: DIN: P2~P0; ANSI: ABEC9~ABEC1; JIS: JIS~JIS0; ISO: CLASS2~NORMAL CLASS; GB/T30794 B~G

- Inquiry ways: The right of the inquiry form, Email, skype, Whatsapp

zhongheng bearing co.,ltd

Email: [email protected] Tel: 86-635-2319970 Mob No.:+86 13963515020 2019-07-08price:best price

delivery time:stock

precision:good and general

30 years professional bearing factory, waiting for your inquiry at any time.

CRBS 508 V C1 bearing 7 pcs,

641TFX01 bearing 3 pcs,

CSXC055 bearing 13 pcs,

YRT1200 bearing 5 pcs,

HM88547/HM88512 bearing 10 pcs,

380690/HC bearing 12 pcs,

9I-1B40-1350-0483-1 bearing 16 pcs,

HYUNDAI R260-5 bearing 11 pcs,

22208-E-K-W33 bearing 14 pcs,

HITACHI EX120-1 bearing 4 pcs,

KG090AR0 bearing 14 pcs,

HSW1800D bearing 5 pcs,

VLA200944-N bearing 16 pcs,

NG075AR0 bearing 6 pcs,