SX011820

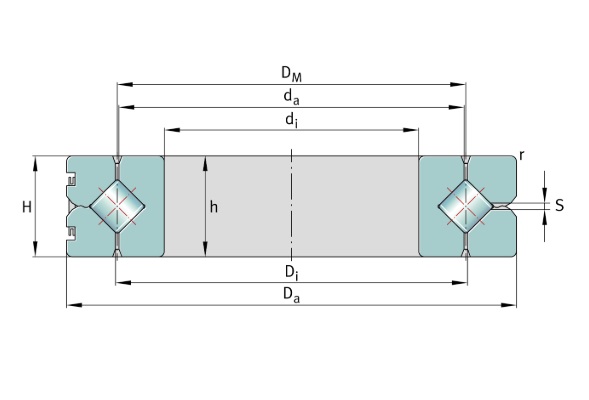

Detailed parameters and installation dimensions:

| Part Number | SX011820 |

| Bearing Type | Crossed roller bearings dimension series 18 to DIN 616 |

| Load | radial, thrust and moment |

| Temperature - T(min) | -30 °C |

| Temperature - T(max) | 80 °C |

| Seal symbol | Open |

| Bore type | Cylindrical |

| Dynamic Axial Capacity - Ca | 27000 N | 6069 lbf |

| Static Axial Capacity - C0a | 102000 N | 22929 lbf |

| Radial Dynamic Capacity - Cr | 19400 N | 4361 lbf |

| Radial Static Capacity - C0r | 40500 N | 9104 lbf |

| Series | SX01 |

| Equivalent | SX 01 1820 |

| Bearing Mass - m | 0.402 kg | 0.886 lb |

| Rolling element pitch circle diameter - DM | 112 mm | 4.409 inch |

| Inner ring - di | 100 mm | 3.937 inch |

| di Tolerance | +0.004/-0.018 mm |

| Outer ring - Da | 125 mm | 4.921 inch |

| Da Tolerance | -0.025 mm |

| Height - H | 13 mm | 0.512 inch |

| H Tolerance | +0.12/-0.12 mm |

| Height of inner ring - hi | 13 mm | 0.512 inch |

| Height of individual ring - h | 13 mm | 0.512 inch |

| h Tolerance | -0.01 mm |

| Inner diameter outer ring - Di | 112.5 mm | 4.429 inch |

| Outside diameter inner ring - da | 111.5 mm | 4.390 inch |

| Dimension Chamfer - r min | 1 mm | 0.039 inch |

| Lubrication hole - S | 1.2 mm | 0.047 inch |

| Rolling Element Type | Cylindrical rollers |

| Rolling Element Material | GCr15 |

| Inner/Outer Ring Material | 50Mn,42CrMo |

| Rows NO. | One |

| Units | Metric |

| Interchangeable | INA SX011820 |

| Fixing screws - Fr perm (friction locking) | 10000 N | 2248 lbf |

| Running accuracy relative to raceway (radial) | 0.010 mm | 0.000 inch |

| Running accuracy relative to raceway (axial) | 0.010 mm | 0.000 inch |

| Standard clearance (radial) - Sr min | 0.005 mm | 0.000 inch |

| Standard clearance (radial) - Sr max | 0.02 mm | 0.001 inch |

| Standard clearance (axial tilting) - Sk min | 0.01 mm | 0.000 inch |

| Standard clearance (axial tilting) - Sk max | 0.04 mm | 0.002 inch |

| Limiting speeds - NG Grease | 680 min–1 |

| Limiting speeds - NG oil | 1360 min–1 |

| Dimensionally identical to ISO dimension series 18 | 818 20 |

| Lubricant | greased |

NOTE: All other trademarks are the property of their respective owners, used for the purpose of compatibility description and product identification only. Tradebearings is not affiliated with, endorsed by, or sponsored by the holders of these trademarks.

SX011820 refers to a specialized type of SX01 Crossed roller bearings dimension series 18 to DIN 616, with dimensions 100 mm (Bore) x 125 mm (OD) x 13 mm (Width), designed for Its rollers are arranged in a 90° perpendicular cross pattern in the V-shaped raceway., primarily used in industrial robot joints, CT scanner gantry, the grease speed ratings: 680 rpm, oil speed ratings: 1360 rpm, featuring One (row) construction , advanced Open, for applications Within a compact space, it simultaneously withstands high-precision radial loads, axial loads, and overturning moments.. the Basic load can reach (dynamic radial:19400, static radial:40500, dynamic axial:27000, static axial:102000), It weight approximately 0.402 kilogram.

- Min. Order: 1 Piece/(SX011820, 100 = ID, 125 = OD, 13 = B, 0.402 kg) or according to different suppliers

- Price: Different brands, different quality, different SX011820 prices, different suppliers and different quality determine different prices, you can ask the supplier in detail for the price according to your own needs.

- Precision Rating: DIN: P2~P0; ANSI: ABEC9~ABEC1; JIS: JIS~JIS0; ISO: CLASS2~NORMAL CLASS; GB/T30794 B~G

- Inquiry ways: The right of the inquiry form, Email, skype, Whatsapp

tradebearings

Email: [email protected] Tel: 86-0578-18167086030 2019-01-01Hi there I’m Minkyu in S,Korea.

I want Bearing RFQ to your company,

Cross Roller bearing, Maker INA sx011820 Model. 1Q’ty, ID 100 * OD 125 * W13.

Send to me best Price and Delivery Times.

Thank you For your help.